Accessories

MMA Welding, also known as Manual Metal Arc Welding or Shielded Metal Arc Welding (SMAW), is a versatile welding process widely used in various industries. In MMA welding, an electric arc is established between a coated electrode and the workpiece, resulting in the melting of the electrode and the base metal. The flux coating on the electrode forms a protective shield, which prevents atmospheric contamination and creates a slag layer that aids in the weld formation. MMA welding is known for its simplicity, portability, and ability to weld a wide range of materials, making it suitable for both indoor and outdoor applications. It is commonly used in construction, repair work, pipelines, and fabrication projects.

Product Advantages

Versatile Welding Capabilities

Our Manual Welding Machine offers a wide range of welding options, allowing users to work with various materials, including steel, aluminum, and copper. Its adaptable design ensures seamless performance across different welding techniques and applications.

Precise and Reliable Welding

With advanced control features, our Manual Welding Machine delivers precise and consistent welds every time. Its intuitive interface enables operators to adjust settings with ease, ensuring optimal weld quality and minimizing the risk of defects or rework.

Enhanced Operator Safety

Safety is paramount, and our Manual Welding Machine prioritizes it. Equipped with comprehensive safety features, such as protective shields and emergency stop mechanisms, it safeguards operators from potential hazards, promoting a secure working environment.

Production Video

This short video showcases the production of handheld welding machines. Watch as skilled technicians assemble components with precision, ensuring quality and durability. The machines undergo rigorous testing for performance and safety. Cutting-edge technology and meticulous craftsmanship come together to create these reliable welding tools. From soldering joints to seamless finishing, every step is carefully executed. Experience the art of welding innovation in this captivating production video.

Applications

Maintenance and Repair

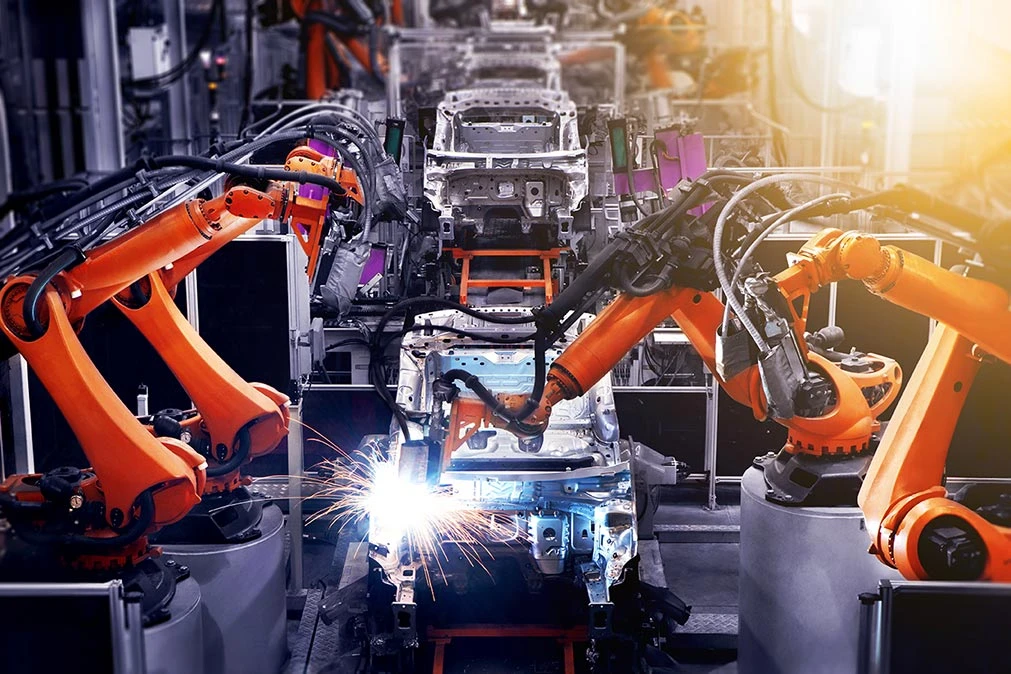

Manufacturing and Assembly

Custom Fabrication

Hobby and DIY Projects

Construction and Structural Welding

Artistic Metalwork

FAQ

A welding machine is a device used to join two pieces of metal together using heat and pressure. It works by generating an electric current that passes through the metal, creating a high-temperature arc that melts the metal and forms a strong bond when it cools.

There are several types of welding machines, including arc welders, MIG welders, TIG welders, and plasma cutters. Each type has its own unique features and applications, catering to various welding needs.

When selecting a welding machine, consider factors such as the type of metals you will be welding, the thickness of the materials, the desired welding process, power requirements, portability, and your skill level.

The welding technique depends on the type of joint, metal thickness, and project requirements. Consult welding experts, refer to welding handbooks, or seek professional advice to determine the most suitable technique for your specific project.

Safety is paramount when working with welding machines. Always wear appropriate protective gear, such as welding helmets, gloves, and flame-resistant clothing. Ensure proper ventilation, work in a well-lit area, and follow safe operating procedures to prevent accidents and protect yourself from harmful fumes and radiation.

Regular maintenance is essential to keep your welding machine in optimal condition. Clean the machine regularly, inspect cables and connections for damage, replace worn-out parts, and follow manufacturer's guidelines for routine servicing and calibration.

Yes, it is possible to weld different types of metals together. However, it may require specialized welding techniques and compatible filler materials to ensure a strong and reliable bond between dissimilar metals.

Inverter-based welding machines offer several advantages, including higher energy efficiency, precise control over welding parameters, lightweight and compact design, and enhanced arc stability. They also often have advanced features like adjustable waveforms and pulsed welding capabilities.

Yes, welding machines can be used for various applications beyond welding. They can also be utilized for cutting metal using plasma cutting or gouging processes, depending on the capabilities of the specific machine.

Learning to weld requires practice and proper training. Consider enrolling in welding courses or apprenticeship programs offered by vocational schools or welding institutes. Additionally, there are online resources, instructional books, and video tutorials available to help you develop your welding skills.