production video

Technical Advantages

- Digital operation interface, dual-knob operation can be more intuitive and diversified settings for welding parameters and operating functions.

- Incorporates a reasonable combination of all-digital dual CPU control technology and soft-switching IGBT inverter technology to achieve good welding performance.

- Through the modification and upgrade of the control software, you can quickly respond to the customer’s special welding process requirements.

- Adopt advanced soft-switching inverter technology.

- Microcomputer control, rich functions and easy maintenance.

- High-frequency pressurized arc ignition, excellent arc starting performance, stable arc during.

- welding, unique output characteristic design, more suitable for filler wire welding, beautiful welding seam.

- Built-in protection circuits for overheating, over current, over voltage, etc.

Technical Parameter

| Model | TIG-315 | TIG-400 | TIG-500 | TIG-630 |

| Voltage range (V) | 3-Phase380±15% | |||

| Frequency (HZ) | 50/60HZ | |||

| Rated input power (KVA) | 9.1 | 20 | 24.5 | 31.5 |

| No-load voltage (V) | 75 | |||

| Rated duty cycle (%) | 60 | |||

| Pre-flow (s) | 0-2 | |||

| Arc lgnition current(A) | 5-100 | |||

| Upper Time(s) | 0-10 | |||

| Down time(S) | 0-10 | |||

| Constant current regulation(A) | 20-315 | 20-400 | 20-500 | 20-630 |

| Arc end current(A) | 20-315 | 20-400 | 20-500 | 20-630 |

| Gas Post(S) | 0.1-15 | |||

| Base current(A) | 20-315 | 20-400 | 20-500 | 20-630 |

| Peak current(A) | 20-315 | 20-400 | 20-500 | 20-630 |

| Pulsed frequency(HZ) | 0.1-200 | |||

| Weight (kg) | 20.4 | 25 | 27 | 40 |

| External dimensions (mm) | 470*250*460 | 540*310*560 | 657*316*660 | |

| Remark: 3~380V/415V/440V can be customized | ||||

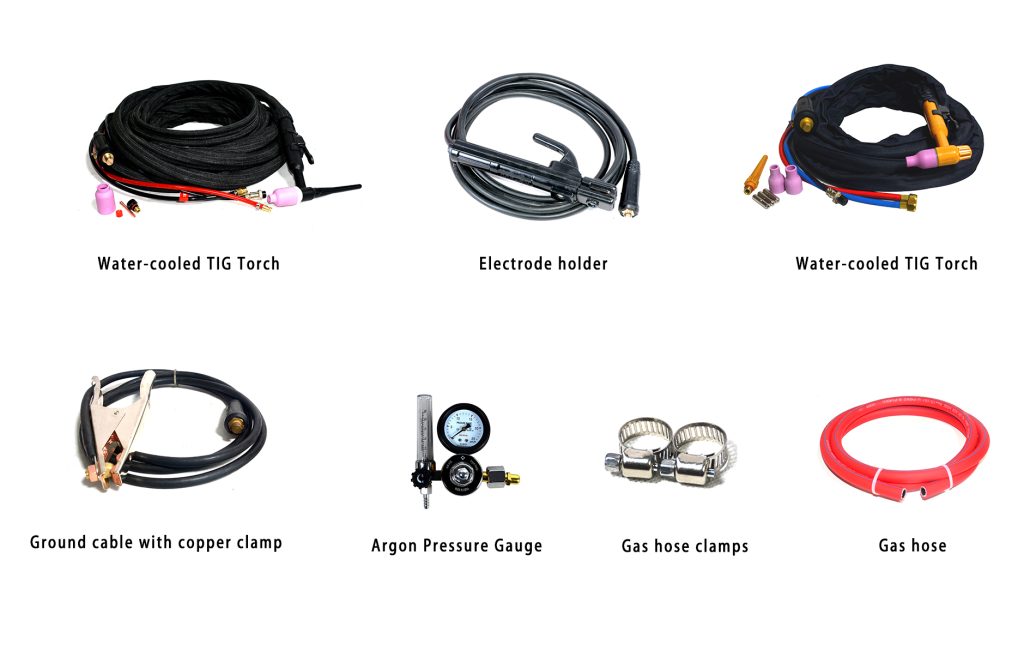

Product Accessories